Related Resources

Agilon Energy Savings of Treated Silicas

Agilon Performance Silica for Tire Overview

Hi-Sil Silica for Tire Overview – North America

Precipitated Silica Products for High-Performance Tire Formulations

PPG Agilon Performance Silica Products

Agilon performance silica also helps the industry address the productivity and environmental challenges associated with manufacturing high-value tires that require silica-filled treads. By enabling a simpler, more efficient mixing process, Agilon performance silica reduces manufacturing complexity and capital investment by increasing mixing throughput, reducing energy consumption, and eliminating essentially all alcohol-related VOC emissions that result from the conventional silica/silane mixing process. Additional benefits of Agilon performance silica include:

- High-temperature mixing without increased viscosity or premature vulcanization

- Elimination of porosity-related extrusion inefficiencies

- Extended shelf life for uncured rubber

- Improved coupling in natural rubber applications

- Lower temperature mixing to avoid natural rubber degradation

Agilon Performance Silica

| Product | Dispers-ibility | Rein-forcing Capability |

CTAB Surface Area (m2/g) |

N2 (BET-5) Surface Area (m2/g) |

SH, Weight % |

Carbon, Weight % |

pH | Residual Salt Type |

Physical Form |

|---|---|---|---|---|---|---|---|---|---|

| Agilon 400G | High | High | 140 | 75 | 0.5 | 4.0 | 6.5 | Na2SO4 | Granule |

| Agilon 454G | High | High | 200 | 140 | 0.5 | 4.0 | 6.5 | Na2SO4 | Granule |

| Agilon 458G | High | High | 200 | 115 | 0.5 | 6.0 | 6.5 | Na2SO4 | Granule |

Agilon Performance Silica Literature

Agilon 400 Performance Silica Technical Data Sheet

Agilon Performance Silica for Tire Overview

Agilon 454 Performance Silica for Truck Tires

Hi-Sil Silica Products

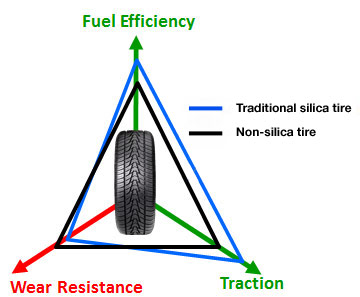

When they were introduced in the 1970s, Hi-Sil silica products were among the first to be used in tire applications, primarily for rubber reinforcement.Since those developments nearly 50 years ago, tire manufacturers have consistently relied on PPG to push the boundaries of quality and innovation. While silica remains critical for rubber reinforcement, the newest generation of classical and highly dispersible Hi-Sil silica materials is helping to redefine the tire industry’s "magic triangle".

From low-surface-area materials for improved winter tire traction and hysteretic properties in non-tread applications, to high-surface-area materials for improved treadwear and uncompromised rolling resistance, PPG works incessantly with tire formulators around the world to develop new Hi-Sil silica materials that meet their specific production and performance requirements.

Typically used in combination with silane coupling agents, these proven, popular tire additives:

- Improve wet traction and fuel efficiency, balancing wear resistance

- Enhance cut-, chip-, chunk-, tear- and cut-growth resistance

- Promote adhesion to brass-coated wire and fabric cord

- Enhance stiffness in the bead area and other non-tread applications

Hi-Sil Reinforcing Silica - North America

| Product | Dispersibility | Reinforcing Capability |

CTAB Surface Area (m2/g) |

N2 (BET-5) Surface Area (m2/g) |

pH | Residual Salt Type |

Physical Form |

|---|---|---|---|---|---|---|---|

| Hi-Sil EZ120G | High | Medium | 125 | 125 | 7.0 | Na2SO4 | Granule |

| Hi-Sil EZ160G | High | High | 160 | 160 | 6.5 | Na2SO4 | Granule |

| Hi-Sil HDP320G | High | High | 160 | 160 | 6.5 | Na2SO4 | Granule |

| Hi-Sil 190G | High | High | 170 | 195 | 7.0 | Na2SO4 | Granule |

| Hi-Sil EZ200G | High | High | 200 | 300 | 7.0 | Na2SO4 | Granule |

| Hi-Sil 210 | Classical | Medium | N/A | 135 | 7.0 | NaCl | Pellet |

| Hi-Sil 243LD | Classical | Medium | N/A | 135 | 7.0 | NaCl | Granule |

| Hi-Sil 134G | Classical | High | 160 | 180 | 6.3 | Na2SO4 | Granule |

Hi-Sil Reinforcing Silica – Europe

| Product | Dispersibility | Reinforcing Capability |

CTAB Surface Area (m2/g) |

N2 (BET-5) Surface Area (m2/g) |

pH | Residual Salt Type |

Physical Form |

|---|---|---|---|---|---|---|---|

| Hi-Sil EZ120G-D | High | Medium | 125 | 125 | 7.0 | Na2SO4 | Granule |

| Hi-Sil EZ160G-D | High | High | 160 | 160 | 6.5 | Na2SO4 | Granule |

| Hi-Sil 190G-D | High | High | 170 | 195 | 7.0 | Na2SO4 | Granule |

| Hi-Sil EZ200G-D | High | High | 200 | 300 | 7.0 | Na2SO4 | Granule |

| Hi-Sil 315G-D | Classical | Medium | 125 | 125 | 7.0 | Na2SO4 | Granule |

| Hi-Sil 255CG-D | Classical | High | 167 | 175 | 6.3 | Na2SO4 | Granule |

| Hi-Sil EZ80G-D | High | Low | 80 | 80 | 7.0 | Na2SO4 | Micro-Granule |

| Hi-Sil EZ90G-D | High | Low | 90 | 90 | 7.0 | Na2SO4 | Micro-Granule |

|

Silene 732 |

HIgh | Low | 33 | 33 | 8.5 | Na2SO4 | Powder |

Hi-Sil Silica Literature

Hi-Sil 190G & Hi-Sil 190G-M Silica

Hi-Sil EZ160G-D Silica brochure

Hi-Sil EZ200G Silica brochure

Hi-Sil EZ80G-D

Hi-Sil EZ90G-D

Agilon and Hi-Sil are registered trademarks of PPG Industries Ohio, Inc.